Korean food has gained global popularity, but keeping its unique flavors intact during export can be tricky. High-capacity lyophilizers play a vital role here. They ensure the food stays fresh, safe, and flavorful. The freeze drying equipment market, valued at $2 billion in 2021, is set to hit $3.72 billion by 2029, growing at 7.68% annually. This growth highlights the increasing demand for reliable solutions like the Dscientz-S Production Freeze Dryer. Choosing the right food lyophilizer, such as the Dscientz-10N/C vacuum freeze dryer for sale Dscie, can make all the difference for exporters aiming to succeed globally.

Key Takeaways

- Large lyophilizers are important for Korean food exporters. They keep food tasty and fresh for longer during shipping.

- Buying energy-saving lyophilizers can lower running costs. These machines use less energy and still dry food well.

- Taking care of lyophilizers and training workers is very important. Good maintenance stops problems and keeps them safe to use.

Understanding Food Lyophilizers

What is a food lyophilizer?

A food lyophilizer is a specialized machine designed for freeze-drying food products. This process removes water content from food through sublimation, preserving its flavor, texture, and nutritional value. Lyophilizers are widely used in industries like food and pharmaceuticals.

| Definition/Example | Description |

|---|---|

| Freeze-drying process | A dehydration technique used in food preservation that involves sublimation of water. |

| Applications | Used in food and pharmaceuticals, including vaccines and biopharmaceuticals. |

| Examples of products | Freeze-dried bacon bars, Bulgarian apricot, ice cream, and various vaccines. |

Freeze-dried foods include fruits, soups, and even ice cream. These products are lightweight, shelf-stable, and easy to rehydrate, making them ideal for export markets.

How lyophilization works in food preservation

Lyophilization involves three key steps:

- Freezing: Food is rapidly frozen at extremely low temperatures.

- Primary drying: Frozen water sublimates directly into vapor under reduced pressure.

- Secondary drying: Remaining moisture is removed to achieve the desired humidity level.

This process typically takes 40 to 100 hours. It creates a porous structure in the food, allowing it to rehydrate quickly while maintaining its original qualities. The use of lyoprotectants ensures the food remains stable during temperature changes, preserving its integrity.

Benefits of using food lyophilizers for exporters

Food lyophilizers offer several advantages for exporters:

- Extended shelf life: Freeze-dried foods can last for years without refrigeration.

- Preservation of quality: The process retains the food’s flavor, texture, and nutrients.

- Lightweight and compact: Reduced water content makes products easier to transport.

- Global market readiness: Lyophilized foods meet international standards for safety and quality.

For Korean food exporters, these benefits are crucial. They ensure traditional flavors and textures remain intact, helping products stand out in competitive global markets.

Specific Needs of Korean Food Exporters

Unique characteristics of Korean food products

Korean cuisine is renowned for its bold flavors, vibrant colors, and unique preparation methods. Many dishes, like kimchi, gochujang, and doenjang, rely on fermentation to develop their signature taste. This process not only enhances flavor but also boosts nutritional value. Korean food often combines contrasting elements, such as sweet and spicy or savory and tangy, creating a balance that appeals to diverse palates worldwide.

Another defining feature is the use of fresh, seasonal ingredients. Traditional recipes emphasize harmony between food and nature, reflecting Korea’s agricultural heritage. For example, banchan (side dishes) often include a variety of vegetables, pickled or seasoned to perfection. These characteristics make Korean food stand out in global markets, but they also pose challenges when it comes to preservation and export.

Challenges in preserving traditional flavors and textures

Preserving the authentic taste and texture of Korean food during export is no small feat. Many traditional dishes, like kimchi, are highly perishable and sensitive to environmental changes. The fermentation process, while essential for flavor, can continue during transportation, altering the product’s quality.

Historical adaptations in Korean cuisine highlight these challenges. For instance:

- The evolution of kimchi demonstrates how early Koreans had to innovate with local ingredients to maintain its signature flavor.

- Practices like Yangnyom culture, which focuses on seasoning and flavor enhancement, emerged to address the limitations of available resources.

- Traditional preservation methods, such as salting and fermenting, were developed to retain both flavor and texture over time.

Modern exporters must balance these traditional techniques with advanced technologies like food lyophilizers. These machines help freeze-dry products, locking in their original qualities while extending shelf life. By doing so, they ensure that global consumers experience the authentic taste of Korea.

Importance of food safety and quality in exports

Food safety and quality are non-negotiable in the export industry. International markets demand strict compliance with safety standards, and Korean food exporters must meet these expectations to succeed. Contaminants, improper storage, or inconsistent quality can damage a brand’s reputation and lead to financial losses.

Freeze-drying technology plays a critical role here. By removing moisture, it prevents microbial growth and extends shelf life without the need for preservatives. This method also retains the food’s nutritional value, ensuring that consumers receive a product that is both safe and wholesome.

For Korean food exporters, maintaining high standards is more than just a regulatory requirement. It reflects a commitment to sharing the rich culinary heritage of Korea with the world. Investing in reliable equipment, like a food lyophilizer, helps achieve this goal while meeting the demands of a competitive global market.

Key Features of High-Capacity Lyophilizers

Large-scale processing capacity

High-capacity lyophilizers are designed to handle large volumes of food products efficiently. This feature is essential for Korean food exporters aiming to meet global demand. By optimizing the primary drying phase, which accounts for about 80% of the lyophilization process, these machines significantly reduce cycle times and energy consumption.

Tip: Effective modeling tools can simulate the lyophilization process, reducing the need for physical experiments and speeding up production. This not only saves time but also enhances plant utilization and lowers costs.

Additionally, historical cycles often have room for improvement. By refining existing processes, manufacturers can increase throughput and reduce operational expenses. For exporters, this means faster production without compromising quality.

Energy efficiency and cost-effectiveness

Energy efficiency is a critical factor when selecting a food lyophilizer. Freeze-drying, while effective, can be energy-intensive. However, modern lyophilizers are designed to minimize energy consumption and operational costs. Here’s a comparison of drying methods:

| Drying Method | Energy Consumption | Operational Costs | Nutrient Retention | Environmental Impact |

|---|---|---|---|---|

| Freeze-Drying (FD) | High | High | High | Significant emissions |

| Hot Air Drying (HD) | Low | Low | Moderate | Lower emissions |

| Spray Drying | Moderate | Moderate | High | More environmentally friendly |

While freeze-drying has higher energy demands, its ability to retain nutrients and extend shelf life makes it the preferred choice for premium food products. Advanced technologies in high-capacity lyophilizers help offset these costs by improving energy efficiency and reducing waste.

Automation and user-friendly operation

Modern food lyophilizers come equipped with advanced automation features, making them easier to operate and maintain. These systems include programmable settings, real-time monitoring, and safety protocols. For example:

- Advanced control systems ensure precise management of the lyophilization process.

- Programmable settings allow operators to customize cycles for different food types.

- Safety features, such as alarms for system malfunctions, protect both the equipment and the product.

The user-friendly design of these machines has earned recognition, such as the Baden-Württemberg Design Award, for innovation and ease of use. For Korean food exporters, this means less downtime, fewer errors, and more consistent results.

Compliance with international food safety standards

Exporting food products requires strict adherence to international safety standards. High-capacity lyophilizers are built to meet these requirements, ensuring that products are safe and of high quality. Compliance methods include:

| Compliance Method | Relevant Standards |

|---|---|

| Vacuum Decay Testing | USP <1207> |

| Lyophilization Process Control | EMA guidelines, cGMP requirements |

| Container-Sealing Mechanisms | EMA guidelines, cGMP requirements |

Maintaining detailed batch records and implementing change control processes are essential for meeting FDA and EMA guidelines. These measures not only ensure compliance but also prepare exporters for regulatory inspections. By investing in a reliable food lyophilizer, Korean food exporters can confidently meet global safety standards.

Customization for diverse food types

Korean cuisine includes a wide variety of products, from fermented dishes like kimchi to delicate snacks like rice cakes. High-capacity lyophilizers offer customization options to accommodate these diverse needs. Key features include:

| Feature | Description |

|---|---|

| Advanced freeze-drying technology | Ensures optimal preservation of nutrients and flavor. |

| Customizable features | Allows adaptation to meet specific product requirements. |

| Flexible control modes | Offers both manual and automatic operation for diverse processing needs. |

| Accurate sensor calibration | Ensures precision in long-term use of process parameters. |

These capabilities allow exporters to tailor the lyophilization process for each product, preserving its unique qualities. For example, a powerful control system records and saves operating data, improving traceability and ensuring consistent results. This level of customization is invaluable for maintaining the authenticity of Korean food in global markets.

Leading Food Lyophilizer Brands and Models

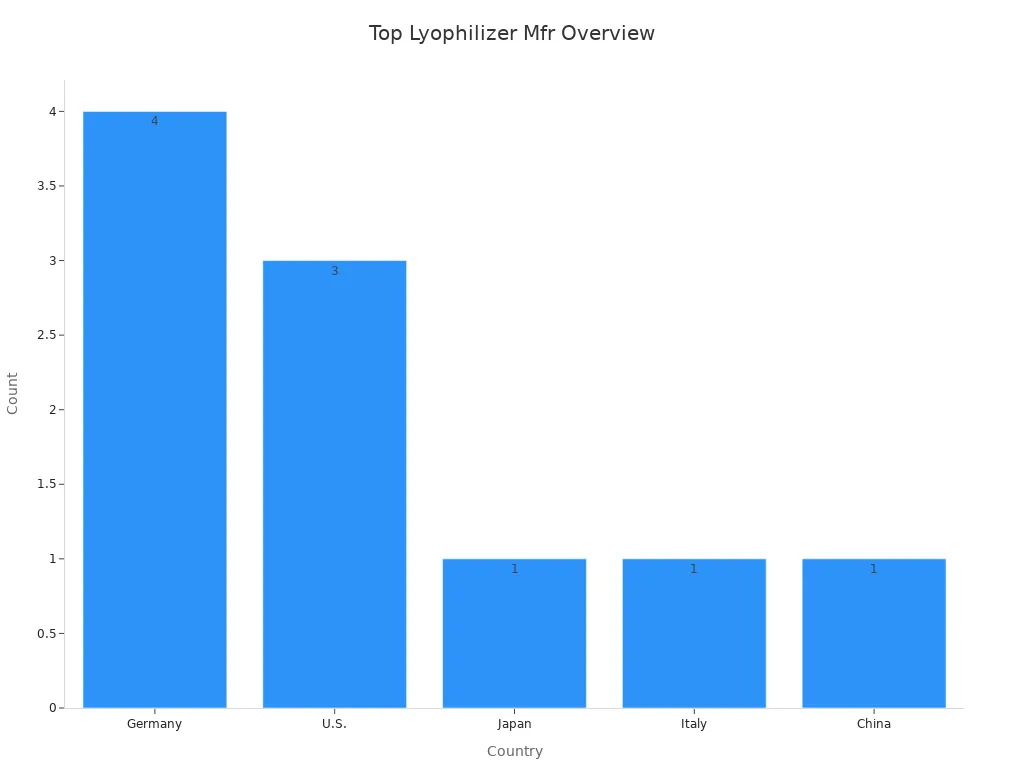

Overview of top manufacturers in the industry

The food lyophilizer market is dominated by several global manufacturers, each contributing innovative solutions to meet diverse industry needs. Companies like GEA Group and Optima Packaging Group from Germany are known for their advanced freeze-drying technologies. Japan’s Azbil Corporation and the U.S.-based SP Industries also lead the way with cutting-edge designs and reliable performance.

Here’s a quick look at some of the top manufacturers:

| Manufacturer | Country |

|---|---|

| GEA Group | Germany |

| Optima Packaging Group | Germany |

| Martin Christ Gefriertrocknungsanlagen GmbH | Germany |

| Azbil Corporation | Japan |

| SP Industries, Inc. | U.S. |

| Tofflon Science and Technology Co. Ltd | China |

| Labconco Corporation | U.S. |

| Millrock Technology Inc. | U.S. |

Examples of high-capacity models like LyoMega and LyoZeta

High-capacity models such as LyoMega and LyoZeta have set benchmarks in the industry. LyoMega, designed for large-scale operations, offers exceptional energy efficiency and precise control over the freeze-drying process. It’s ideal for exporters handling bulk quantities of food products. On the other hand, LyoZeta focuses on versatility, accommodating a wide range of food types while maintaining consistent quality. Both models are equipped with advanced automation features, making them user-friendly and reliable for long-term use.

Key differentiators between popular brands

When comparing brands, several factors stand out. German manufacturers like GEA Group and Martin Christ emphasize engineering precision and energy efficiency. U.S.-based companies, such as SP Industries and Labconco, focus on automation and compliance with international safety standards. Meanwhile, Azbil Corporation from Japan is known for its compact designs and innovative control systems.

Tip: Exporters should consider their specific needs—whether it’s large-scale capacity, energy savings, or customization—when choosing a food lyophilizer.

By understanding these differentiators, Korean food exporters can select equipment that aligns with their operational goals and ensures the preservation of their products’ unique qualities.

Maintenance and Operational Tips

Regular maintenance for optimal performance

Regular maintenance keeps lyophilizers running smoothly and ensures consistent product quality. Neglecting upkeep can lead to inefficient drying cycles, higher operational costs, and compromised food quality. Industries like pharmaceuticals face strict regulations for drying equipment, and failing to meet these standards can have serious consequences. For Korean food exporters, maintaining high standards is equally critical to meet international safety requirements.

Routine checks on components like vacuum pumps, refrigeration systems, and sensors help prevent unexpected breakdowns. Cleaning and replacing worn parts on schedule also extend the machine’s lifespan. A well-maintained lyophilizer not only reduces downtime but also saves money in the long run by avoiding costly repairs.

Tip: Create a maintenance log to track inspections and repairs. This simple step can improve efficiency and ensure no task is overlooked.

Staff training for efficient operation

Proper training equips staff with the skills needed to operate lyophilizers effectively. Employees who understand the science behind freeze-drying can better manage the process and troubleshoot issues. Training programs that focus on calibration, quality control, and compliance are especially valuable.

| Training Focus | Benefits |

|---|---|

| Instrument calibration | Ensures accurate process conditions. |

| Quality and compliance | Improves product consistency and safety. |

| Role-based training | Simplifies learning and boosts efficiency. |

In 2017, 30% of FDA warning letters for data integrity issues were linked to inadequate training. This highlights the importance of investing in comprehensive programs. Simplified, role-specific training can also enhance operational performance and ensure compliance with global standards.

Reducing downtime and extending equipment lifespan

Minimizing downtime is key to maximizing the lifespan of a lyophilizer. Using durable materials like corrosion-resistant steel can significantly increase equipment longevity. For instance, some manufacturers report a 40-50% improvement in lifespan by adopting advanced materials. Additionally, energy recovery technologies, now common in industrial dryers, improve efficiency by reusing up to 90% of heat.

- Optimize drying cycles to reduce energy use and wear on components.

- Schedule preventive maintenance to address minor issues before they escalate.

- Invest in high-quality parts and materials to enhance durability.

Process optimization not only saves energy but also reduces strain on the machine, ensuring it operates at peak performance for years. For exporters, this means fewer interruptions and more reliable production schedules.

Note: A proactive approach to maintenance and training can transform lyophilizer operations, delivering long-term benefits for both efficiency and product quality.

High-capacity lyophilizers are game-changers for Korean food exporters. They preserve flavors, extend shelf life, and meet global safety standards. With the freeze-dried food market surpassing $1 billion in 2021 and growing, investing in energy-efficient, customizable equipment is essential. Choosing the right lyophilizer ensures quality, boosts efficiency, and sets exporters up for global success.

FAQ

What foods can be freeze-dried using high-capacity lyophilizers?

Most foods can be freeze-dried, including fruits, vegetables, meats, and fermented products like kimchi. Lyophilizers preserve flavor, texture, and nutrients effectively.

How long does the freeze-drying process take?

Freeze-drying typically takes 40 to 100 hours, depending on the food type and machine settings. Advanced models optimize drying cycles for faster results.

Are high-capacity lyophilizers energy-efficient?

Yes, modern lyophilizers use advanced technology to reduce energy consumption. Features like heat recovery systems improve efficiency and lower operational costs.

Post time: Apr-17-2025